Intelligent Industrial Robot Palletizer

Date:2017/10/08 New Product Product Views:1380

Brand: SANSAN

Model: SS-C-18-6-12

Benefits:

• To automatically feed empty trays or cartons, up to 36. If no trays, warning will be sent out in advance.

• To automatically locate materials, can grasp materials up to 12 at one single time.

• The grabbing module of each material can independently control lifting, grasping and free placement.

• Full Servo Cylinder and Bus Control System adopted, to achieve faster and more accurate placement.

• Modularization design adopted for wider applicability.

Video:

Product Introduction:

Our robot can stack,& dissemble the pallets and load & unload automatically the workpieces on the production machine by the gripping actions of the robot arm. Our robot system achieves the automation of the pallets in the workshops for reducing the labors and improving the productivity.

Product Features:

• To be connected with ERP system and mobile app, equipped with AGV, and finally achieve intelligent production

• Independently developped control system

• Place accurately the pallets for avoding the abrasion of the materials

• Stack multi pallets and transfer the whole pallet

• Adjust automatically the gripping rate according to the production rate of the injection molding machine

• Singlet online, simple & fast

• Collect the materials by the AGV Robot

• Connect with ERP system and APP terminal

Product Advantage:

• Space saving: compact structure, integrated processing axis

• Modular machine design leads to the low costs–Customs-made solution for the bulk production

• Quality guarantee: Stable quality provided by the automation process

• Lower the costs with the automation process and stably high quality

• High Flexibility: Adapt easily the pallet and the carrier of the workpieces

• Multi Function: Apply fastly and directly to other production steps.

• Suitable for all of the general and custom-made sizes of the pallets

• Increase the decision making power with the automatic manufacture process

• Buffer and feed the production spare parts

• Suitable for multi products: automobile parts, ball bearing, sliding wheel, valve, fan wheel, window, circuit board, electric valve, rotary valve

• Provide automatically the manufacturing machines by the stacker crane equipped with the integrated process axis.

Product Features:

1、Load automatically max 51 empty pallets. Alarm automatically when there isn’t any pallet.

2、Locate automatically the materials. Grip max 12 pcs of materials at the same time.

3、Each gripping module can control independently the lifting, picking and free placing.

4、Controlled by the full electric actuator total line for achieving the high speed and high accuracy.

5、Modular Design,Wide Application Range

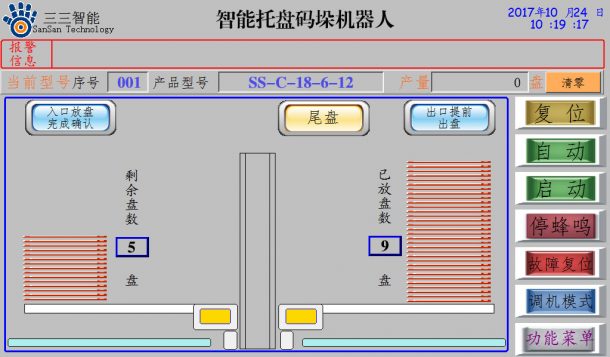

Graphic Illustration:

1、Feeding Conveyor

Function: Store the material box, Transfer the material box

2、Transfer Module

Function: Transfer the material box onto the pallet module

3、Pallet Module

Function: Move correctly the material box and place orderly the workpieces with the collaboration of the osculum module.

4、Mould module

Function: Transport orderly the workpieces out from the injection molding machine

5、Osculum Module

Function: Take out the workpiece from the mould module and place orderly the workpieces with the collaboration of the pallet module.

6、Discharge & Transfer Module

Function: Transfer the material disc filled with workpieces from the pallet module to the discharge conveyor.

7、Discharge Conveyor

Function: Discharge the piled material discs for the easy transportation

Technical Parameters:

• Rate:10s/Mold

• Dimension: (L)2350 x (W)1850 x (H)2300mm

• Volt/Power:380V;3KW;50Hz

• Total Gas Consumption:0.6m3/min

• Pallets Capacity:Max 51 pcs of empty pallet

• Molds Shifting Range:30-37mm

• Air Pressure:0.6-0.8MPa

Product Application:

Apply widely in the industries of the machine manufacturing, installation, printing and injection molding.

Previous: Full-Automatic Pad Printing Machine

Next: Robot Polishing Unit